BIOMASS &

WASTE-TO-ENERGY

SOLUTIONS

30

+EXPERIENCE YEARS

50

+INVENTION PATENT

100

+NUMBER OF EMPLOYEES

20,000

m²COMPANY AREA

ABOUT US READ MORE >

Wuxi UPA Thermal is a leading manufacturer of high-efficiency biomass boiler systems, committed to accelerating the global transition to carbon-neutral industrial and commercial heating.

Since Year 1991,we have engineered cutting-edge thermal solutions that harness renewable biomass resources, empowering businesses to achieve energy independence while significantly reducing environmental impact.

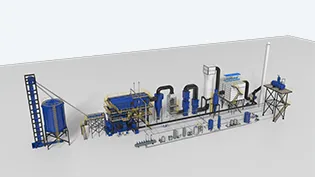

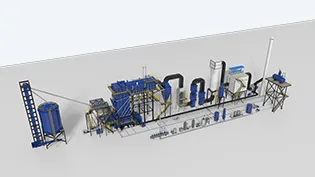

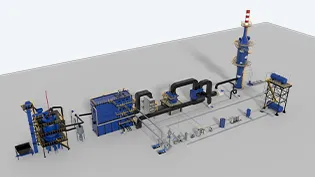

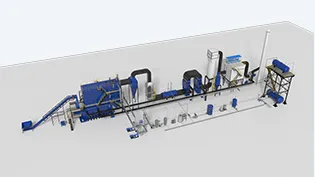

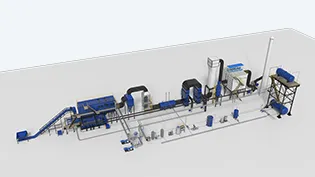

BIOMASS GASIFICATION

STEAM BOILER

10 Tons/H

BIOMASS-FIRED CHAIN GRATE

THERMAL OIL HEATER

12 MILLION Kcal/H

APPLICATION INDUSTRY

The Common Choice of the Entire industry--Dedicated to Providing Green Boiler Solutions

WHAT'S NEWS

When quality meets reliability - News updates showcase your trusted boiler partner

09-20-2025

POWERMAX Concludes a Successful Showcase at Electric & Power Indonesia 2025

09-19-2025

Powermax at NABC 2025: Showcasing Pyrogreen Biochar Systems and Biowatt Gasification Solutions

Powermax was honored to participate in the North American Biochar Conference (NABC) 2025, a premier gathering for innovators, researchers, and practitioners in the biochar and bioenergy sectors. At this event, we presented two of our flagship technologies—Pyrogreen carbonization systems and Biowatt skid-mounted gasification units—demonstrating how biomass can be transformed into both renewable energy and carbon removal solutions. At the Pyrogreen booth, visitors explored how our advanced carbonization furnaces convert agricultural residues, forestry byproducts, and other biomass feedstocks into high-quality biochar. This biochar not only contributes to long-term carbon sequestration but also improves soil fertility, offering a practical pathway to sustainable agriculture and climate resilience. Meanwhile, the Biowatt integrated gasification systems drew significant attention for their containerized, modular design—an efficient and scalable solution for decentralized power generation. Beyond producing clean syngas for energy, these units also generate biochar as a valuable byproduct, creating a unique bridge between renewable energy production and carbon removal markets. Over the course of the conference, our team engaged in meaningful discussions with farmers, project developers, policy experts, and researchers. Topics ranged from feedstock diversification and project feasibility to the growing role of biochar in carbon credit markets. Demonstration videos and technical dialogues at our booth further highlighted the commercial readiness of our solutions. Conference sessions on policy, certification, and market development provided valuable insights into the evolving biochar industry, reinforcing our commitment to advancing technology and fostering collaboration across the value chain. As NABC 2025 concluded, we reflected on an inspiring week of knowledge exchange and partnership building. Powermax extends sincere thanks to the organizers and all visitors who joined us. With renewed momentum, we look forward to driving forward the adoption of biochar and biomass gasification technologies—supporting both a low-carbon energy future and the global carbon removal agenda.

09-12-2025

A Comprehensive Guide to Reciprocating Grate Biomass Boilers: Technology and Applications

Introduction As industries worldwide seek sustainable alternatives to fossil fuels, biomass combustion has emerged as a critical technology for reducing carbon emissions and operational costs. Among various large-scale biomass technologies, reciprocating grate boilers stand out for their exceptional fuel flexibility and reliability. This technical overview explores the features and benefits of this established combustion technology. Biomass Combustion Technologies: Comparative Analysis Three primary technologies dominate large-scale biomass combustion: Technology Key Characteristics Best Suited For Suspension Firing Requires high-quality dried and pulverized fuels. Delivers highest efficiency but limited fuel flexibility. Best suited for premium fuels like pelletized wood Fluidized-Bed Combustion Good efficiency with moderate fuel flexibility. Higher maintenance costs due to bed material erosion and potential agglomeration issues. A variety of fuels with good moisture control. Grate Firing Technology Exceptional fuel flexibility, robust operation with lower maintenance requirements, and proven reliability for diverse biomass fuels. Heterogeneous and lower-quality biomass fuels. Technical Specifications: Reciprocating Grate Steam Boiler Our biomass-fired reciprocating grate steam boilers offer advanced engineering with these key specifications: Model Range: SZL8 to SZL35 Capacity: 8-35 t/h steam production Thermal Power: 5.6-25 MW Operating Pressure: 1.25-2.5 MPa Steam Temperature: 193-226°C Design Efficiency: ≥88% Water Volume: 13.5-35 m³ Heat Exchange System: Main body surface area: 278-739 m² Economizer surface area: 240-1,521 m² Engineering Advantages Fuel Flexibility Compatible with wood chips, olive husks, rice husks, and industrial wood waste Handles biomass with calorific value of 2300-4000 Kcal/kg Accommodates moisture content from 10-50% Processes particles with equivalent diameter of 30-50mm Control Systems Fully automated temperature and pressure control Precision combustion management Comprehensive safety systems Remote monitoring capabilities Environmental Performance NOx, SO2, and particulate emissions below stringent international standards Sustainable carbon-neutral operation Compliance with strict emission regulations Maintenance Features Strategic access points for internal inspection Simplified maintenance procedures Minimal downtime requirements Easy component replacement Thermal Efficiency Advanced structural design maximizes heat transfer High-grade materials ensure optimal performance ≥88% design efficiency across operational range Installation Advantages Modular structure reduces installation time Factory-assembled components Reduced site preparation costs Quick commissioning process Applications and Industries Ideal For: Wood processing facilities, Agricultural processing plants,Industrial manufacturing, District heating systems, Power generation applications. Fuel Compatibility: Forest biomass residues, Agricultural waste products, Industrial wood waste, Various biomass pellets, Energy crops Food Industry Medicine Industry Nestlé requires thermal energy for its food processing operations. UPA THERMAL delivers customized energy solutions featuring biomass-fired chain grate steam boilers. These systems utilize direct biomass combustion to generate process steam for Nestlé's production facilities. Malaysia's AIN Medical Group requires thermal energy for pharmaceutical manufacturing. UPA THERMAL provides customized energy solutions integrating POWERMAX gasification systems. This technology converts biomass (EFB briquettes) into syngas, which fuels specialized biomass gasification thermal oil heater to deliver high-precision thermal fluid for AIN's production processes. Papermaking Industry Materials Industry Guangxi Fangsheng Paper requires thermal energy for its paper manufacturing operations. UPA THERMAL delivers customized energy solutions utilizing biomass-fired reciprocating grate steam boilers. These systems efficiently convert biomass fuel (primarily sawdust) into process steam for Fangsheng Paper's production needs. Giteri Environmental Technology requires thermal energy for eco-material production. UPA THERMAL provides customized energy solutions featuring biomass gasification technology. The system converts biomass into syngas, which fuels thermal oil boilers to deliver precise thermal fluid for Giteri's manufacturing processes. Performance Data Steam Output Parameters Operational Characteristics Main steam connections: DN150-DN300 Negative pressure combustion system Feed water connections: DN50-DN80 Stable operation across load range Safety valve sizing: 65-150mm Quick response to demand changes Drain connections: DN50 standardized Consistent steam quality output Why Choose Reciprocating Grate Technology? Proven Reliability Economic Benefits Sustainability Features Established technology with numerous installations Lower fuel costs through waste utilization Carbon-neutral energy production Robust construction for long service life Reduced preprocessing requirements Waste reduction through biomass utilization Consistent performance in various applications Minimal operational maintenance Compliance with environmental standards Long-term cost stability Support for circular economy principles Conclusion Reciprocating grate biomass boiler technology represents a robust and efficient solution for industrial steam generation. With exceptional fuel flexibility, high efficiency, and reliable operation, this technology provides a practical pathway to sustainable energy production while maintaining operational economics. The combination of proven combustion technology with advanced control systems ensures optimal performance across various biomass fuels, making it an ideal choice for facilities seeking to utilize available biomass resources while reducing environmental impact. For specific technical requirements or application consulting, our engineering team provides comprehensive support from initial assessment through commissioning and operation.

09-13-2025

Company Successfully Showcased at Enlit Asia 2025 and FIEE Brazil, Strengthening International Energy Collaboration

Our company recently participated simultaneously in Enlit Asia 2025 in Bangkok, Thailand, and the FIEE International Energy Exhibition in São Paulo, Brazil. These two major international energy events gathered industry leaders and professionals from around the world. With our advanced biomass gasification solutions, our booth became a hotspot, attracting clients and partners from Asia, Latin America, and Europe, and fostering in-depth technical exchanges and cooperation discussions. During the three-day Enlit Asia exhibition, we presented our innovative technology that converts agricultural, forestry, and industrial residues into clean energy. This solution not only meets regional heating and industrial power demands but also supports carbon reduction goals. Throughout the exhibition, many industry professionals visited our booth and engaged with our team, showing great interest in the clean energy pathways we proposed. At the same time, the FIEE exhibition was successfully held in São Paulo. Over its four days, our company showcased proven expertise and technological advantages in biomass gasification, while engaging extensively with Latin American energy companies, industrial users, and technology providers. Our booth consistently attracted strong attention, and our technical team held high-level discussions with visitors on regional energy transition, green economic development, and future collaboration opportunities, further expanding our presence in the Latin American market. This dual exhibition presence fully demonstrated our company’s innovative capabilities and international strategic vision in the global clean energy sector. By engaging with partners from diverse regions, we not only enhanced brand recognition in international markets but also laid a solid foundation for future cooperative projects. We will continue to advance with professional technology and practical actions, working hand in hand with global partners to drive a smarter, low-carbon, and sustainable energy future. Media Contact:Company NameContact Person: Abby LuPhone: +86 13075566506Email: abby.lu@powermaxgasifiers.com; abby.lu@pyrogreen-energy.com Website: https://www.powermaxgasifiers.com/

08-19-2025

Biomass Boiler/Furnace Manufacturers - UPA Thermal

What is a biomass boiler? A biomass boiler is a boiler equipment that primarily uses agricultural and forestry waste as fuel. It generates thermal energy by burning renewable agricultural residues such as wood chips, straw, rice husks and other similar materials, which can be converted into various forms including steam, hot water or thermal oil. Biomass boilers are widely applied in industrial processing, district heating, and power generation sectors. UPA Thermal is a leading ISO 9001 certified biomass fired thermal oil boiler manufacturer, supplier, and exporter, offering turnkey solutions for industries worldwide. With over 30 years of experience in designing and manufacturing low-emission, high-efficiency biomass boilers, we help clients reduce carbon emissions while improving operational efficiency. [Request a Quote for Your Biomass Boiler Project →] Biomass gasification steam boiler Biomass-fired Chain Grate Steam Boiler Biomass-fired Reciprocating Grate Steam Boiler Biomass Gasification Thermal Oil Heater UPA Thermal's biomass boiler equipment creates significant value for investors: Value 1. High Fuel Flexibility , Compatible with Multiple Biomass Types Our biomass boilers are designed for exceptional fuel adaptability, supporting a wide range of solid biomass fuels, including wood chips, rice husk, palm fiber, and industrial wood waste. They can efficiently process fuels with high moisture content (10-50%) and low calorific value (2,300-4,000 kcal/kg), ensuring stable operation even with challenging fuel conditions. Value 2. High Efficiency & Energy Savings , Industry-Leading Thermal Utilization With gasification combustion technology and innovative structural design, our biomass boilers achieve 88%-91% thermal efficiency, far surpassing traditional coal-fired boilers (typically 75%-85%). Value 3. Outstanding Environmental Performance , Meets Strict Emission Standards All our industrial biomass boilers incorporate low-NOx combustion and staged air supply technology, ensuring PM, SO₂, and NOx emissions are well below the latest EU and Chinese environmental standards. Value 4. Smart & Modular Design , Reducing Total Cost of Ownership Fully automated control system (PLC-based) for real-time adjustments of temperature, pressure, and airflow, minimizing manual intervention and improving safety. Biomass boiler models of UPA Our Biomass Boiler Models : Designed for Maximum Efficiency UPA Thermal provides a wide range of high-quality biomass boilers. Each model is designed for industrial use and available for purchase worldwide through our factory, supplier, and exporter services. Biomass steam boiler Biomass Gasification Steam Boiler: A high-efficiency boiler where fuels are gasified prior to combustion, achieving ≥91% thermal efficiency. Low NOx and SO₂ emissions make it ideal for environmentally conscious industries. Chain Grate Steam Boiler: Directly burns solid biomass with broad fuel adaptability (10–50% moisture content), designed for efficiency ≥88%. Reciprocating Grate Steam Boiler: Features dynamic grate agitation to enhance combustion for high-ash or irregular fuels (Ø30–50 mm). Easy maintenance and high reliability. Biomass thermal oil boiler Biomass Gasification Thermal Oil Heater: Delivers indirect heat transfer via high-temperature thermal oil (320°C), eliminates phase-change risks, achieves thermal efficiency of 88%, and reduces ash fouling risk through gas combustion. Chain/Reciprocating Grate Thermal Oil Heater: Directly combusts solid biomass, supports low-calorific-value fuels (2,300–4,000 kcal/kg), and features modular construction for reduced installation cycles. Biomass Steam Boiler Series – Parameters and Specifications he following biomass steam boiler models are manufactured by UPA Thermal and available for purchase directly from our factory or through our global supplier network. Each boiler series is designed to meet diverse industrial requirements while maintaining high efficiency and environmental compliance. Parameter Biomass Gasification Steam Boiler Biomass-fired Chain Grate Steam Boiler Biomass-fired Reciprocating Grate Steam Boiler Model SZL8-SZL35 SZL8-SZL35 SZL8-SZL35 Rated evaporation (t/h) 8/10/15/20/25/35 8/10/15/20/25/35 8/10/15/20/25/35 Thermal power (MW) 5.6/7/10.5/14/18/25 5.6/7/10.5/14/18/25 5.6/7/10.5/14/18/25 Working pressure (MPa) 1.25/1.6/2.5 1.25/1.6/2.5 1.25/1.6/2.5 Steam temperature (°C) 193/204/226 193/204/226 193/204/226 Feed water temperature (°C) 104 104 104 Design efficiency (%) ≥91% ≥88% ≥88% Boiler water volume (m³) 14.2/15/21/24/25/35 13.5/13.5/18/23/28/35 13.5/13.5/18/23/28/35 Heat exchange area Main body (m²): 283-753 Main body (m²): 278-739 Main body (m²): 278-739 Economizer (m²): 264-1258 Economizer (m²): 240-1521 Economizer (m²): 240-1521 Applicable fuel Biomass gas Solid biomass: Same as left Calorific value: 2,300-4,000 kcal/kg Moisture: 10-50% Particle size: Ø30-50mm (L<100mm) Combustion type Negative pressure combustion Negative pressure combustion Negative pressure combustion Main steam pipe (mm) DN150-DN300 DN150-DN300 DN150-DN300 Feed water pipe (mm) DN50-DN80 DN50-DN80 DN50-DN80 Drain pipe (mm) DN50 DN50 DN50 Safety valve diameter (mm) 65+80 to 125+150 65+80 to 125+150 65+80 to 125+150 Biomass Thermal Oil Heater Series – Parameters and Specifications UPA Thermal offers a range of biomass-fired thermal oil heaters for industrial applications. All models are designed for global export, ensuring clients receive high-quality boilers directly from the manufacturer. Parameter Biomass Gasification Thermal Oil Heater Biomass-fired Chain Grate Thermal Oil Heater Biomass-fired Reciprocating Grate Thermal Oil Heater Model YLW-4100SII to YLW-25000SII YLW-4100SII to YLW-25000SII YLW-4100SII to YLW-25000SII Heating capacity (×10⁴ kcal/h) 350/600/900/1200/1600/2200 350/600/900/1200/1600/2200 350/600/900/1200/1600/2200 Thermal power (MW) 4.1/7/10.5/14/19/25 4.1/7/10.5/14/19/25 4.1/7/10.5/14/19/25 Design pressure (MPa) 1.1 1.1 1.1 Max. operating temperature (°C) 320 320 320 Design efficiency (%) 85.5/88/88/88/88/88 85.5/88/88/88/88/88 85.5/88/88/88/88/88 Medium circulation (m³/h) 260/520/800/1000/1000/1300 260/520/800/1000/1000/1300 260/520/800/1000/1000/1300 Main oil pipe (mm) DN200 to 2×DN400 DN200 to 2×DN400 DN200 to 2×DN400 Applicable fuel Biomass gas (LCV ≥1,280 kcal/kg) Biomass gas (LCV ≥1,280 kcal/kg) Biomass gas (LCV ≥1,280 kcal/kg) Combustion type Negative pressure combustion Negative pressure combustion Negative pressur

08-08-2025

Final Day at Thailand Palm Oil Expo – Don’t Miss Us!

🌿 Final Day at Thailand Palm Oil Expo – Don’t Miss Us!It’s the last day of the show, and we’re still going strong here in Thailand!Drop by our booth to discover how our biomass gasification and carbonization systems can help turn palm waste into clean energy and valuable biochar. Let’s make the most of the final hours – see you soon!#PalmOil #ThailandExpo #Biochar #Gasification #CleanEnergy #BiomassSolutions #Sustainability #UPAThermal

Tailored Solutions, Timeless Service——

We Keep Your Operations Running