Biomass Boiler Solutions

Efficiently convert biomass to clean energy,

meeting your heating needs sustainably and affordably.

ABOUT

BIOMASS

BOILERS

Biomass boilers work by converting organic materials (e.g., agricultural waste, wood) into heat through combustion or gasification. Rooted in centuries of sustainable fuel use, they’ve evolved from traditional heating to advanced, low-emission systems driven by sustainability goals.

Unlike coal, fossil fuels, or oil—which release legacy carbon and pollutants—biomass is “carbon-neutral” (recycling plant-absorbed CO2), cuts NOx/SOx emissions by 50-80%, and utilizes waste feedstocks, cutting reliance on finite fuels. This makes them a cleaner, cost-effective alternative for industries seeking to decarbonize while optimizing energy efficiency.

FUEL RANGE

Multiple types of biomass waste can be used as fuel for combustion

HOW WE DO IT

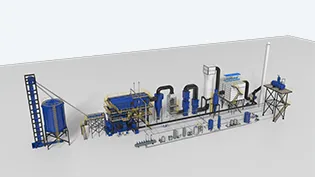

Guangxi Fangsheng Paper requires thermal energy for its paper manufacturing operations. UPA THERMAL delivers customized energy solutions utilizing biomass-fired reciprocating grate steam boilers. These systems efficiently convert biomass fuel (primarily sawdust) into process steam for Fangsheng Paper's production needs.

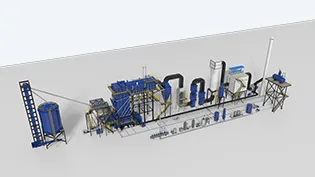

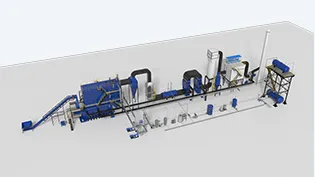

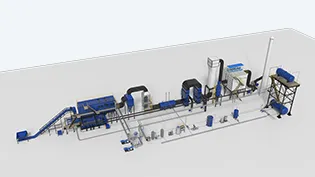

NAFINE Chemical Group requires thermal energy for its chemical production processes. UPA THERMAL provides customized energy solutions that utilize POWERMAX gasification systems. These systems convert biomass (wood chips) into syngas. This syngas is then used to fuel specialized gasification steam boilers, generating steam to meet NAFINE Chemical Group's operational needs.

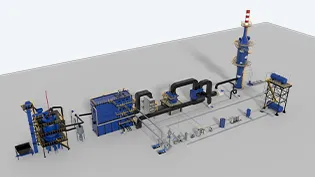

Nestlé requires thermal energy for its food processing operations. UPA THERMAL delivers customized energy solutions featuring biomass-fired chain grate steam boilers. These systems utilize direct biomass combustion to generate process steam for Nestlé's production facilities.

For more industries, please click "INDUSTRY" in the navigation bar.

Tailored Solutions, Timeless Service——

We Keep Your Operations Running

.webp)