A Comprehensive Guide to Reciprocating Grate Biomass Boilers: Technology and Applications

Introduction

As industries worldwide seek sustainable alternatives to fossil fuels, biomass combustion has emerged as a critical technology for reducing carbon emissions and operational costs. Among various large-scale biomass technologies, reciprocating grate boilers stand out for their exceptional fuel flexibility and reliability. This technical overview explores the features and benefits of this established combustion technology.

Biomass Combustion Technologies: Comparative Analysis

Three primary technologies dominate large-scale biomass combustion:

|

Technology |

Key Characteristics |

Best Suited For |

| Suspension Firing | Requires high-quality dried and pulverized fuels. Delivers highest efficiency but limited fuel flexibility. | Best suited for premium fuels like pelletized wood |

| Fluidized-Bed Combustion |

Good efficiency with moderate fuel flexibility. Higher maintenance costs due to bed material erosion and potential agglomeration issues. |

A variety of fuels with good moisture control. |

| Grate Firing Technology |

Exceptional fuel flexibility, robust operation with lower maintenance requirements, and proven reliability for diverse biomass fuels. |

Heterogeneous and lower-quality biomass fuels. |

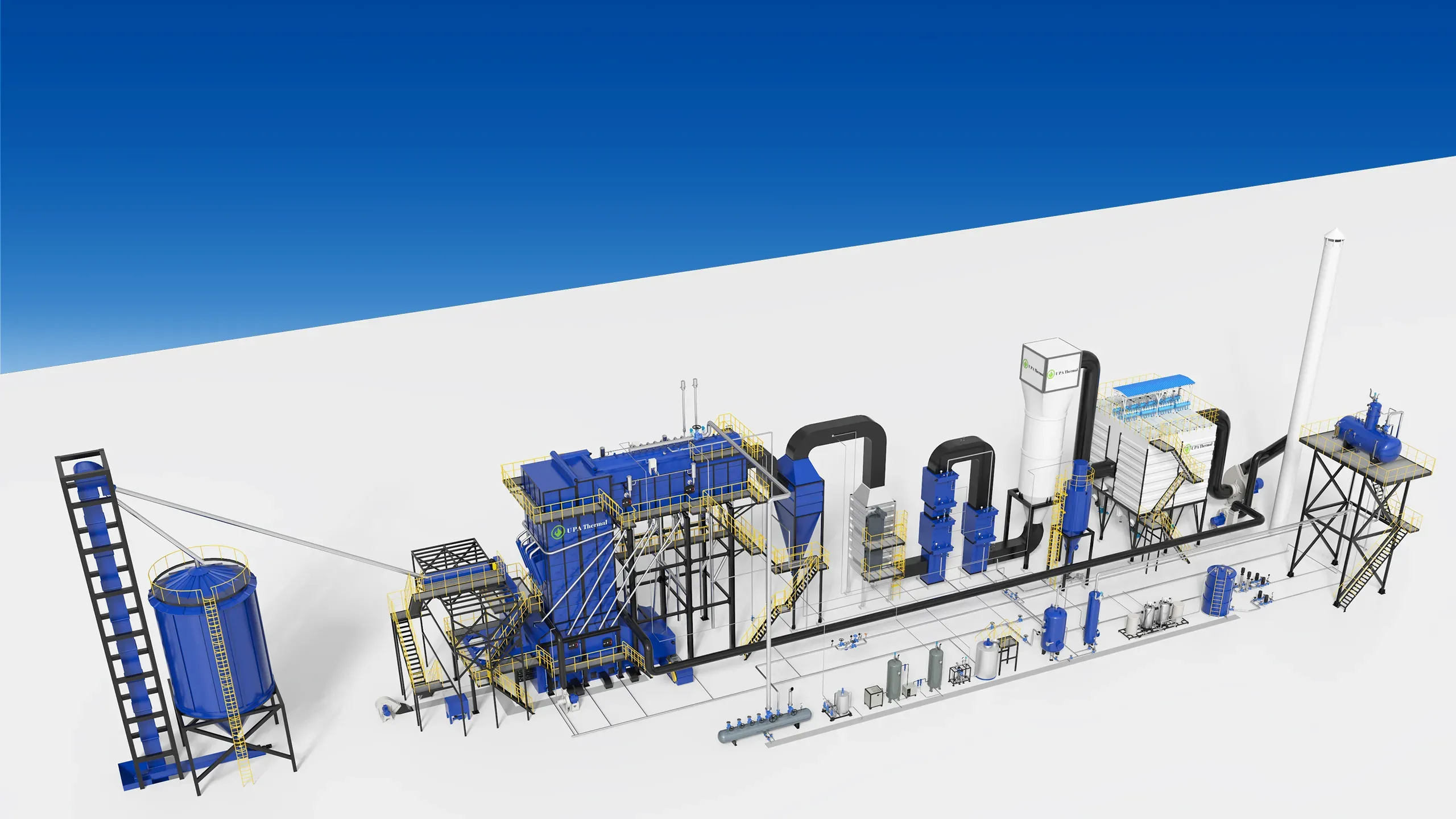

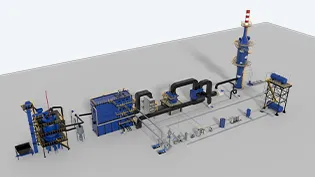

Technical Specifications: Reciprocating Grate Steam Boiler

Our biomass-fired reciprocating grate steam boilers offer advanced engineering with these key specifications:

|

Model Range: SZL8 to SZL35

Capacity: 8-35 t/h steam production

Thermal Power: 5.6-25 MW

Operating Pressure: 1.25-2.5 MPa

Steam Temperature: 193-226°C

Design Efficiency: ≥88%

Water Volume: 13.5-35 m³

|

Heat Exchange System:

Main body surface area: 278-739 m²

Economizer surface area: 240-1,521 m²

|

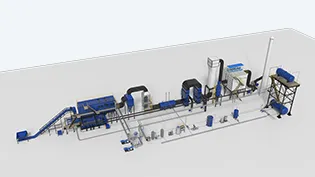

Engineering Advantages

Fuel Flexibility

Compatible with wood chips, olive husks, rice husks, and industrial wood waste Handles biomass with calorific value of 2300-4000 Kcal/kg Accommodates moisture content from 10-50% Processes particles with equivalent diameter of 30-50mm |

Control Systems

Fully automated temperature and pressure control Precision combustion management Comprehensive safety systems Remote monitoring capabilities |

Environmental Performance

NOx, SO2, and particulate emissions below stringent international standards Sustainable carbon-neutral operation Compliance with strict emission regulations |

Maintenance Features

Strategic access points for internal inspection Simplified maintenance procedures Minimal downtime requirements Easy component replacement |

Thermal Efficiency

Advanced structural design maximizes heat transfer High-grade materials ensure optimal performance ≥88% design efficiency across operational range |

Installation Advantages

Modular structure reduces installation time Factory-assembled components Reduced site preparation costs Quick commissioning process |

Applications and Industries

Ideal For:

Fuel Compatibility:

Food Industry

|

Medicine Industry

|

|

Nestlé requires thermal energy for its food processing operations. UPA THERMAL delivers customized energy solutions featuring biomass-fired chain grate steam boilers. These systems utilize direct biomass combustion to generate process steam for Nestlé's production facilities. |

Malaysia's AIN Medical Group requires thermal energy for pharmaceutical manufacturing. UPA THERMAL provides customized energy solutions integrating POWERMAX gasification systems. This technology converts biomass (EFB briquettes) into syngas, which fuels specialized biomass gasification thermal oil heater to deliver high-precision thermal fluid for AIN's production processes. |

|

|

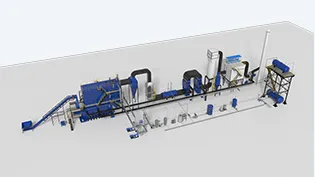

Papermaking Industry

|

Materials Industry |

|

Guangxi Fangsheng Paper requires thermal energy for its paper manufacturing operations. UPA THERMAL delivers customized energy solutions utilizing biomass-fired reciprocating grate steam boilers. These systems efficiently convert biomass fuel (primarily sawdust) into process steam for Fangsheng Paper's production needs. |

Giteri Environmental Technology requires thermal energy for eco-material production. UPA THERMAL provides customized energy solutions featuring biomass gasification technology. The system converts biomass into syngas, which fuels thermal oil boilers to deliver precise thermal fluid for Giteri's manufacturing processes. |

|

|

Performance Data

| Steam Output Parameters | Operational Characteristics |

| Main steam connections: DN150-DN300 | Negative pressure combustion system |

| Feed water connections: DN50-DN80 | Stable operation across load range |

| Safety valve sizing: 65-150mm | Quick response to demand changes |

| Drain connections: DN50 standardized |

Consistent steam quality output |

Why Choose Reciprocating Grate Technology?

Proven Reliability |

Economic Benefits |

Sustainability Features |

| Established technology with numerous installations | Lower fuel costs through waste utilization | Carbon-neutral energy production |

| Robust construction for long service life |

Reduced preprocessing requirements | Waste reduction through biomass utilization |

| Consistent performance in various applications | Minimal operational maintenance | Compliance with environmental standards |

| Long-term cost stability |

Support for circular economy principles |

Conclusion

Reciprocating grate biomass boiler technology represents a robust and efficient solution for industrial steam generation. With exceptional fuel flexibility, high efficiency, and reliable operation, this technology provides a practical pathway to sustainable energy production while maintaining operational economics.

The combination of proven combustion technology with advanced control systems ensures optimal performance across various biomass fuels, making it an ideal choice for facilities seeking to utilize available biomass resources while reducing environmental impact.

For specific technical requirements or application consulting, our engineering team provides comprehensive support from initial assessment through commissioning and operation.

Tailored Solutions, Timeless Service——

We Keep Your Operations Running

Back

Back